We provide solutions for a wide range of applications. We work across major technology platforms and deliver value at all stages of manufacturing from design, build and support to improve quality, efficiency and safety of your plant operations.

Today's dairy processing plants face enormous challenges. Many facilities are still using outdated dairy automation systems and must now make major upgrades in spite of difficult economic circumstances. As dairy processing regulations tighten and profit margins narrow, consumers are demanding a broader selection of healthy, grab-and-go dairy products, dairy processing plants must develop a sustainable approach to innovation in order to succeed in this environment. NATC understands these needs and can help you optimise your dairy processing lines and achieve operational excellence.

We have years of consulting experience in all segments of dairy production, providing complete turnkey automated industrial production lines. We are also supported by our partner Automation System(AS) Hellas, we have developed trusting relationships with many companies on an international scale. We've successfully implemented and integrated a range of systems for dairy operations of all sizes, with expertise in the following markets: cheese, cultured dairy, butter, process cheese, yogurt, etc.

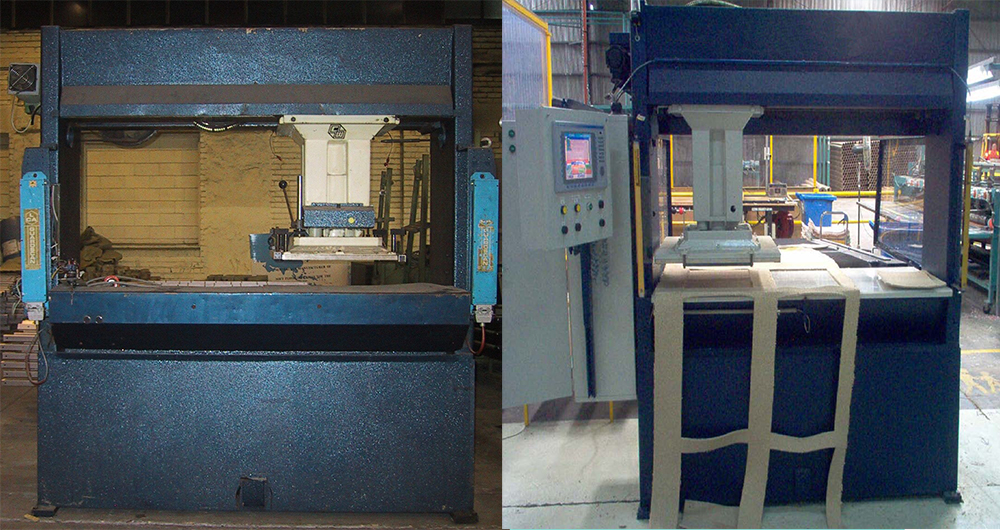

We have teamed with AS Hellas to provide special prefabricated units for dairy and cheese plants. These are ready tested and ready for installation. The units are supplied with flexible automation software and detailed operator manuals.

NATC can help:

Ensure FDA compliance by maintaining clean-in-place (CIP) systems that incorporate the legal interlocks

Comply with ISA-88 batch control standard, ISA-95 enterprise control standards and the Pasteurized Milk Ordinance (PMO)

Minimise milk loss by eliminating leaks and implementing CIP systems with accurate milk recovery sensors

Read More

.png)